Home / Technology Platforms / Custom Fabrication

Custom Fabrication

3DGS’ unique design and manufacturing techniques deliver high isolation of signal to signal and signal to ground, allowing custom design and cost-effective, scalable fabrication of countless devices.

Antennas

Antennas with integrated feed networks and baluns can be created with exceptional gain and high isolation to ground. The ability of 3DGS technology to manufacture precise features and ‘floating’ transmission lines means considerably better performance than PCB or LTCC-based structures.

ADAS/5G/6G Radio on Glass (RoG)

3DGS has developed a patented ultra-low-loss empty Substrate Integrated Waveguide (eSIW) technology for high frequency Antenna-in-Package (AiP) and Radio-on-Glass (RoG) applications between 60 and 300GHz. This technology integrates all the necessary elements for a full RF Front-End into a single device, making it ideal for 5G, and 6G applications.

Diode Mounts

Laser sub mount edge wraps using precision 3DGS manufacturing techniques allow improved performance and reduced package size. Micron footprints, precision angles and integrated electrical connections are now possible.

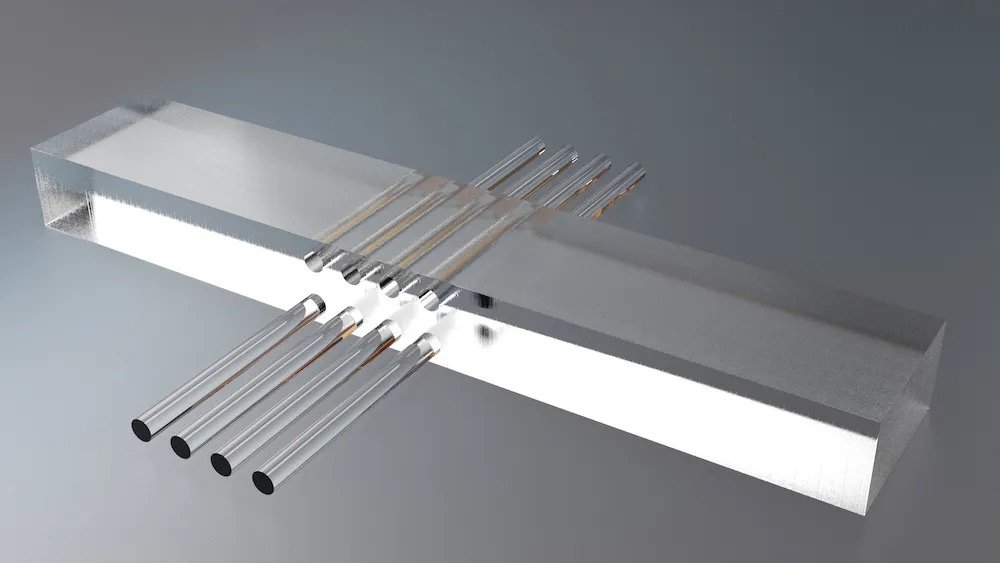

Fiber Aligners

3DGS technology allows precise creation of high-density fiberoptic arrays that simplify integration, alignment and assembly to reduce cost. Hole-to-hole alignment of less than 0.5 um can be achieved.

Micro-Cavities

Precise, micron-scale cavities can be created using 3DGS fabrication techniques with no chipping, fractures or breaks. Create cavities of any shape or size, with depths of up to 800 µm.

RF Bridges

Impedance – matched custom RF bridges improve circuit-to-circuit electrical connections. The use of 3DGS glass delivers low loss performance and easy device handling.

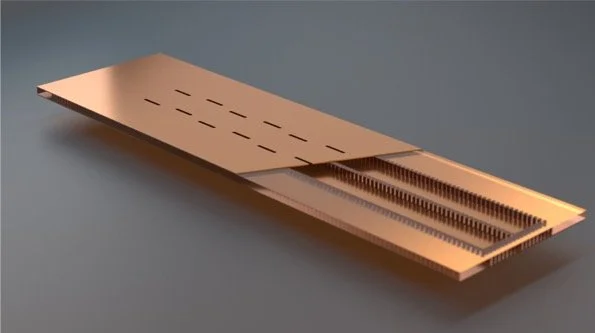

SiW

Substrate Integrated Waveguide (SIW) technology using 3DGS manufacturing techniques results in an air-filled device with an effective Dk ≃ 1.0. Ultra-low loss is achieved through micron-scale manufacturing precision to deliver SIWs ideal for integration into AiP devices.

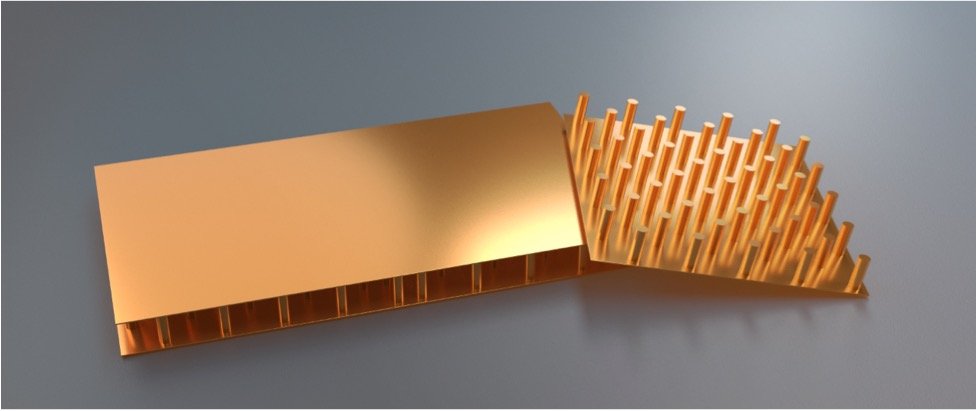

Thermal

Thermal performance is enhanced through the use of unique structure designs leveraging 100% copper pillars for minimized stress and improved thermal cycling performance over the long-term. Package size can be significantly reduced and thermal transfer significantly improved as compared to other approaches.