APEX® Glass Technology and Properties

3DGS’ patented APEX® glass is unlike other glass substrates in that processing transforms patterned areas of the substrate to become ceramic, while others remain glass. Etching of the ceramic areas creates 3D microstructures while maintaining the integrity of the glass area. The process allows a low-cost, high-volume, wafer-level production solution ideal for miniaturized, high performance electronic devices.

APEX® GLASS ADVANTAGES

APEX® Glass offers several advantages over traditional I/C packaging materials, such as silicon, laminates, and laser processed glass, including

Batch manufacturing enables low-cost production

Multi-faceted production enables greater integration of active components lowering production and packaging costs

Smooth surfaces and ultra-small through holes with tight densities provide industry-leading electrical routing densities

Broad spectrum transparency is ideal for many optoelectronics and opto-RF applications

Better material constants compared against laminates and silicon enables a 66% chip reduction allowing for 2.2 times more parts per wafer

Micro-fracture free production of through holes ensures lower loss and better reliability compared against laser processed glass

Glass-enabled systems integration

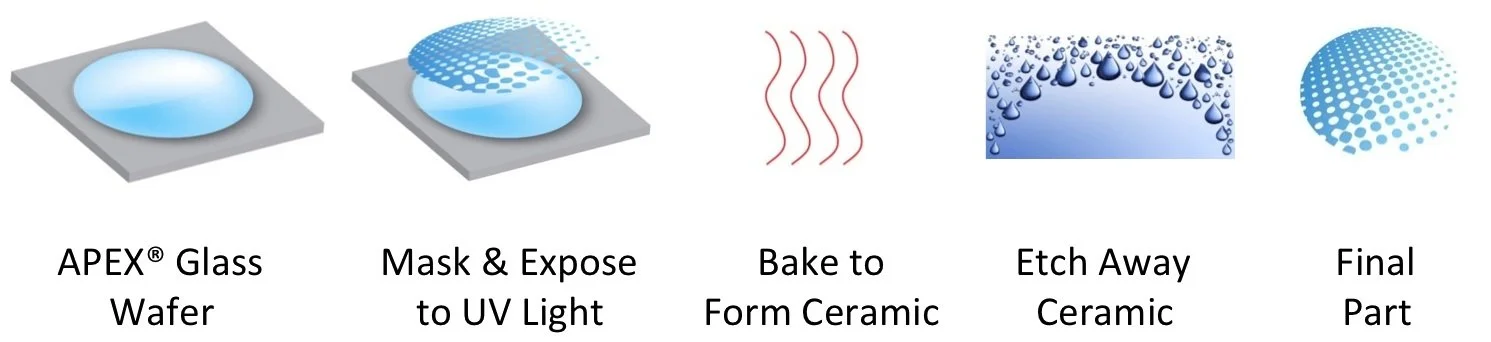

THE APEX® GLASS MANUFACTURING PROCESS

APEX® Glass is processed using a simple three-step process:

EXPOSE: The wafer is masked using a photomask (no photoresist) and then exposed to UV light

BAKE: the exposed wafer is baked to convert the exposed regions into a ceramic; and

ETCH: the exposed and baked wafer is etched in a diluted acid removing the ceramic regions.

This simple manufacturing process enables our APEX® Glass as a systems integrator and gives a high degree of flexibility and integration of multiple processing steps to create monolithically integrated electronic packages.

Using this manufacturing approach the final product may:

Contain a variety of through glass via shapes, sizes and densities

Contain multiple etched features including through glass vias, cavities, lines, channels, and wells

Be fully glass, fully ceramic, or hybrids of the two states

3DGS has a variety of advanced foundry capabilities. To learn more please visit our Custom Design & Fabrication webpage.

APEX® Glass Properties

OVERVIEW

APEX® Glass is a photosensitive glass-ceramic material ideally suited for the microstructuring of precision features. APEX® Glass is ideally suited for a number of markets including RF signal conditioning, IC packaging, life science, and integrated photonics. APEX® Glass is produced and sold exclusively by 3D Glass Solutions, Inc.

PHYSICAL PROPERTIES

APEX® Glass is an Alumino-silicate glass with a medium coefficient of thermal expansion ideally positioned between silicon (3ppm/K) and copper (17ppm/K). APEX® Glass also has a high glass transition temperature enabling an elevated post-processing thermal window for downstream microfabrication needs.

| DESCRIPTION | SPECIFICATION |

|---|---|

| Coefficient of Thermal Expansion | 10 ppm/K |

| Glass Transition Temperature (Tg) | 452°C |

| Density | 2.35 g/cm³ |

| Young’s Modulus | 80 GPa |

| Thermal Conductivity | 1.5 W/mK |

ELECTRICAL PROPERTIES

APEX® Glass is used extensively for a number of microwave and RF applications. Leveraging APEX® Glass’ electrical characteristics with advanced manufacturing and designs is only possible with photo-definable glasses enables electronic structures with very high Q, low loss, with greater data transfer rates at lower power consumption.

| DESCRIPTION | SPECIFICATION |

|---|---|

| Electrical Resistivity | 1012 ohm-cm |

| Frequency (GHz) | 0 – 20 |

| Loss Tangent | 0.0102 |

| Dielectric Constant | 6.4 |

OPTICAL PROPERTIES

APEX® Glass is an ideal material for a number of photonics and optoelectronic applications. Combine APEX® Glass’ electrical integration and optical properties to create small and powerful optics systems.

| SPECIFICATION | GLASS | CERAMIC | NOTE |

|---|---|---|---|

| 1550nm | 93% | 82% | Tested with 1mm thick samples. |

| RI | GLASS | CERAMIC | PRECIPITATE |

|---|---|---|---|

| 532nm | 1.5283 | 1.5293 | 1.5260 |

| 633nm | 1.5238 | 1.5249 | 1.5216 |

| 986nm | No Data | 1.5166 | 1.5137 |

| Abbe Number | 63.8988 |

APEX® Glass Technology

APEX® Glass is not like traditional glasses. It contains special sensitizers that allow unique anisotropic 3D features to be formed through a simple exposure step. This “photo-structurable glass” combines batch manufacturing processes with standard IC processing toolsets to provide a low-cost, high-volume, production solution.

APEX® Glass’ microfabrication ability is ideally suited for the wafer level packaging of electronic packages. Applications span many industries including 2.5D and 3D packaging, RF packages (inductors, antenna, etc.), optoelectronics, and microcavities among others.